Ukuphepha komsebenzi

1, qaphela uphawu oluyisixwayiso emshinini, sebenzisa ngokuphepha.

2, vimbela umlilo noma ukuqhuma eduze komshini

3, Ungavuli iphaneli yokulawula ngaphambi kokucisha amandla

4, qiniseka ukuthi ucingo alunamonakalo

5, qiniseka ukuthi izintambo azikho uxhumano lwe-virtual

6, qiniseka ukuthi ukuma kwesimo esiphuthumayo bese udonsa ucingo r ukusebenza ngokujwayelekile futhi uzisebenzise ngendlela efanele engozini.

7, Ungathinti indawo yokushisa ephezulu

8. Geza ngamanzi abandayo uma ushile;uma kushisa nge-PUR, unganyakazi, noma uzokhipha inyama, udinga ukuthunyelwa esibhedlela.

Ukunaka

1.ungafaki indandatho, iwashi lesandla, izindwangu ezixegayo uma usebenza.

2.bopha izinwele uma usebenza

3.Gqoka amagilavu, izibuko nezingubo ezimpintshayo uma usebenza

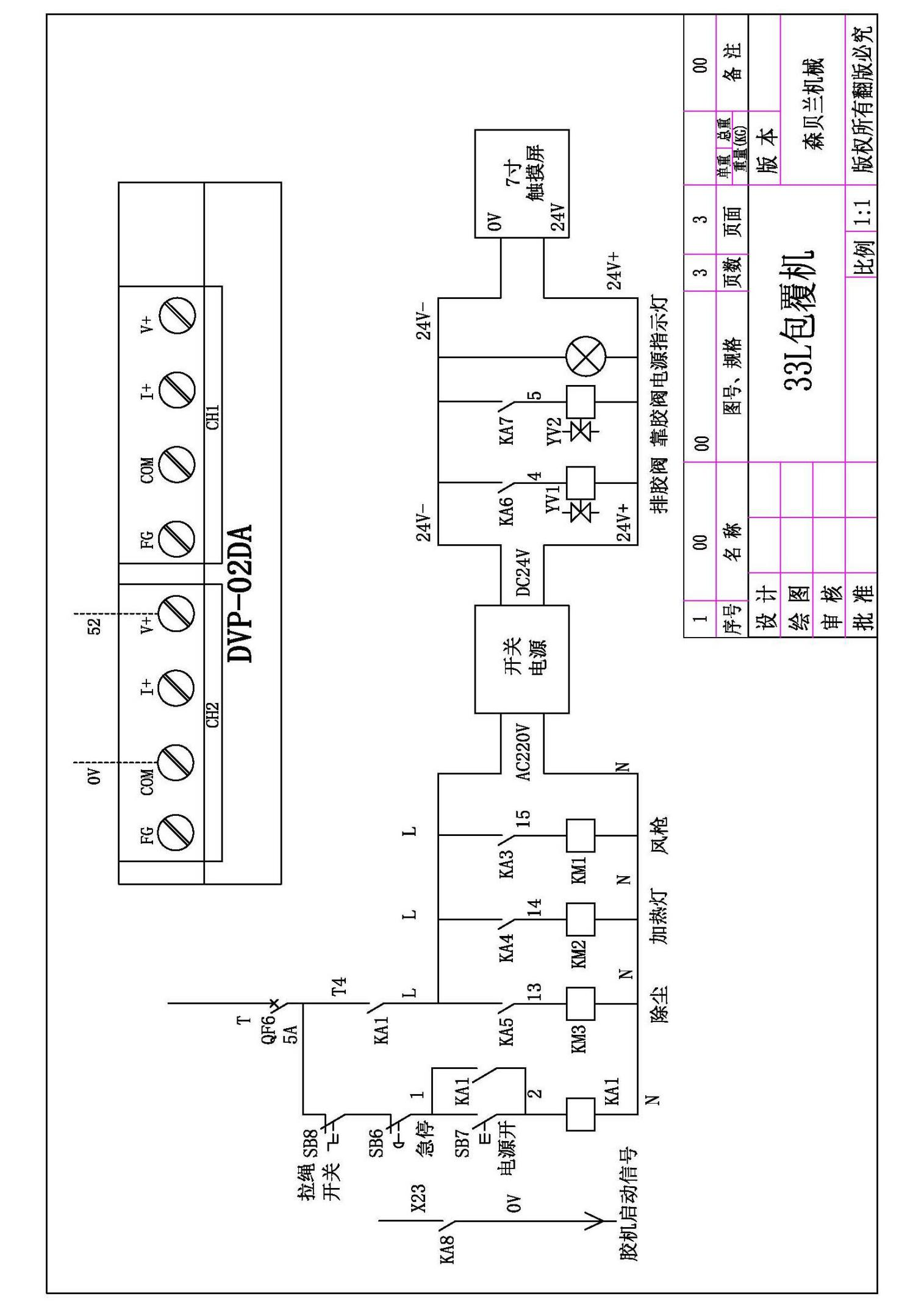

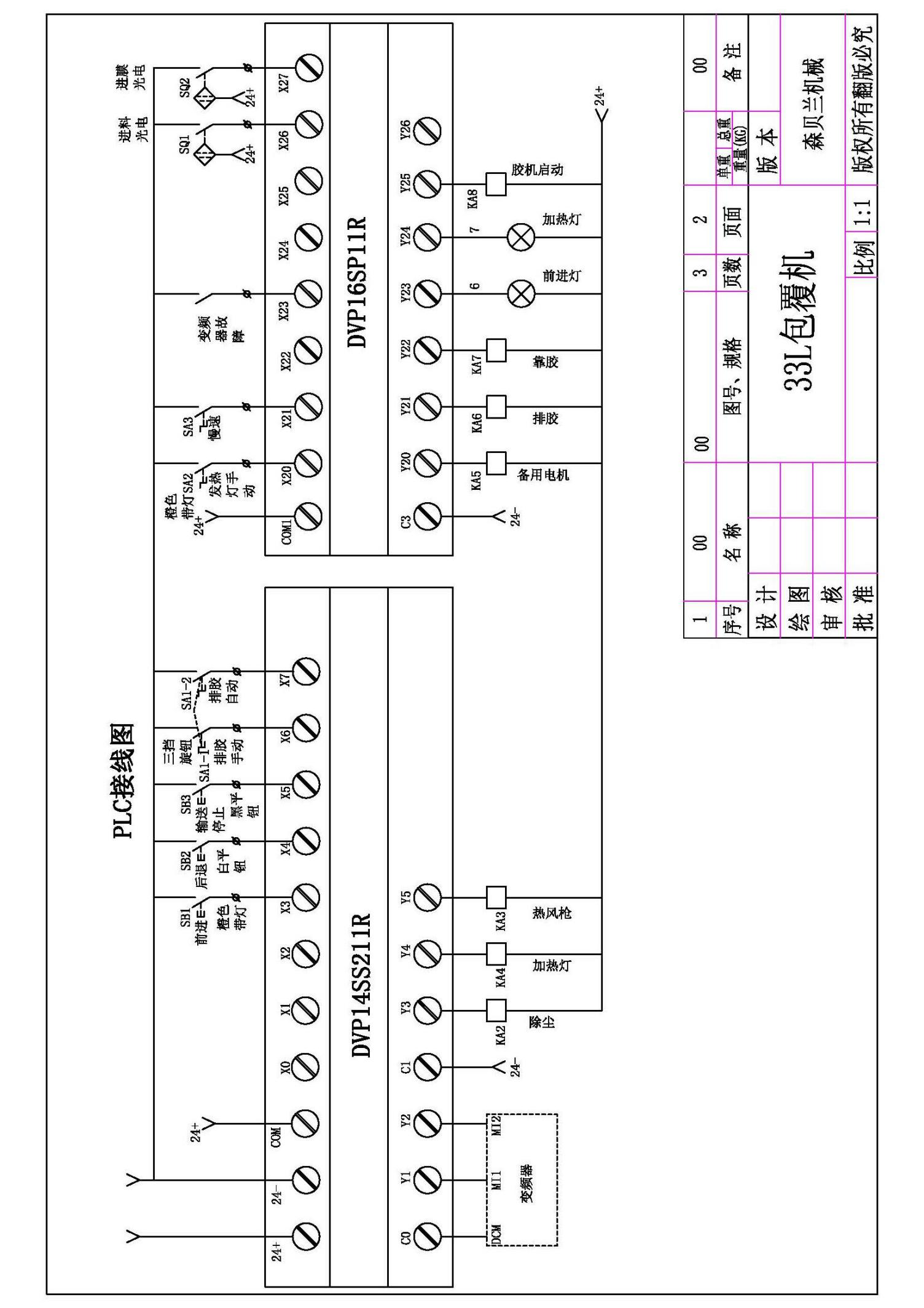

Ⅱ, ukwethulwa kwephaneli yokulawula

umsebenzi kanye nepharamitha yalo mshini isethwe esikrinini esithintayo

Qala umshini ukuze uvule ikhasi, thinta ku-interface

Ipharamitha yokusebenza komshini wesikrini (isivinini somsebenzi, ubuningi njll.), futhi ingakhetha futhi ilungise amapharamitha.

Isikrini sokuthinta sihlanganisa amagama, izinombolo, izithonjana, nenkinobho ethintayo nendawo yenombolo.

Inkinobho yokuthinta: isithonjana sokuthinta ukuze ukhethe umsebenzi esikrinini (okufana nekhasi phezulu naphansi, ukusetha kabusha counter).

Iwindi le-Pop: lingavula futhi livale ngokuthinta inkinobho ngqo esikrinini.Iwindi le-Pop linekhathalogi, iqembu kanye nephaneli, ezokwethula izinsuku zepharamitha.

Inkinobho yokuthinta: isithonjana esikusikrini r siyashintsheka esishintsha ipharamitha ngokuthinta.shintsha shintsha ngaso sonke isikhathi ngokuthinta.Okufana nokushintsha CHA no-VALIWE, Okuzenzakalelayo kanye Nesandla.

Indawo yenombolo: amapharamitha r ahlukaniswe ukufunda kuphela futhi ayashintsheka.Izobonisa ikhibhodi ngokuthinta inombolo eshintshayo, izinombolo zepharamitha yokokufaka kanye ne-ENT ngokuqinisekile, noma i-ESC yokukhansela.

2.1 isingeniso senkinobho yokuthinta

iya ekhasini elilandelayo

iya ekhasini elilandelayo

emuva ekhasini lokugcina

emuva ekhasini lokugcina

,

, thinta ukwandisa izinombolo, lesi sithonjana sihlala sinezinombolo, thinta ukuze ukhulise izinombolo ezithile ngakho konke ukuthinta.

thinta ukwandisa izinombolo, lesi sithonjana sihlala sinezinombolo, thinta ukuze ukhulise izinombolo ezithile ngakho konke ukuthinta.

,

, thinta ukuze unciphise izinombolo, lesi sithonjana sihlala sinezinombolo, thinta ukuze unciphise izinombolo ezithile ngakho konke ukuthinta.

thinta ukuze unciphise izinombolo, lesi sithonjana sihlala sinezinombolo, thinta ukuze unciphise izinombolo ezithile ngakho konke ukuthinta.

Inkinobho yokuvala: amapharamitha omsebenzi avaliwe, thinta ukuze umiselele ON isimo.

Inkinobho yokuvala: amapharamitha omsebenzi avaliwe, thinta ukuze umiselele ON isimo.

Inkinobho YOKUVULA: ipharamitha yokusebenza IVULIWE, thinta ukuze umiselele isimo SOKUVAMILE.

Inkinobho YOKUVULA: ipharamitha yokusebenza IVULIWE, thinta ukuze umiselele isimo SOKUVAMILE.

Inkinobho ezenzakalelayo: umsebenzi uzenzakalela, thinta ukuze umiselele isimo sesandla.

Inkinobho ezenzakalelayo: umsebenzi uzenzakalela, thinta ukuze umiselele isimo sesandla.

inkinobho yesandla: umsebenzi ungowakho, thinta ukuze umiselele isimo esizenzakalelayo.

inkinobho yesandla: umsebenzi ungowakho, thinta ukuze umiselele isimo esizenzakalelayo.

Kuze kube manje, izinkinobho zokuthinta, imingcele, idethi eshintshekayo yokulawula imishini yomsebenzi ohlukile.

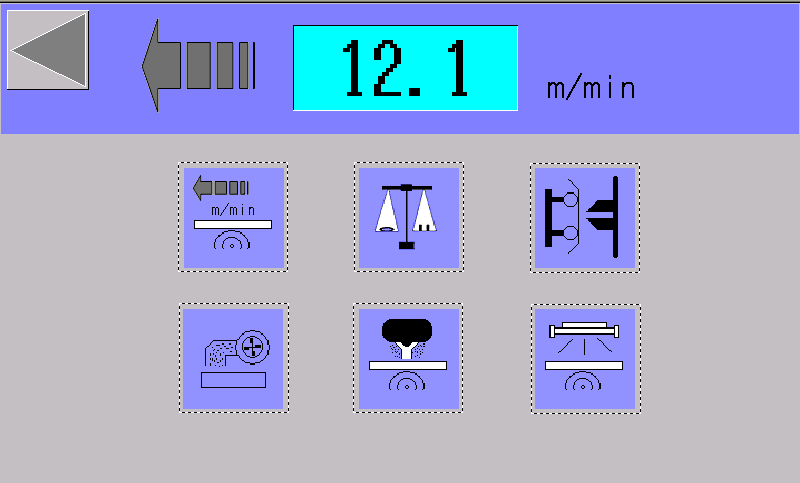

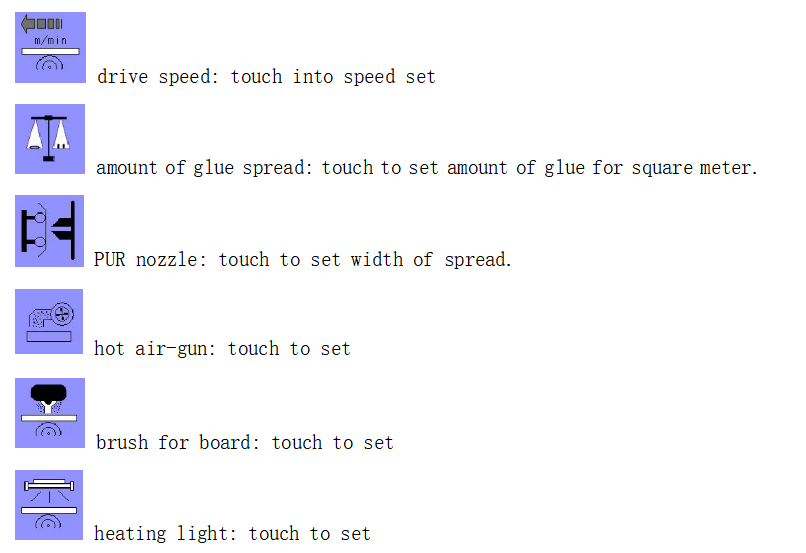

2.2 isingeniso sekhasi lemenyu

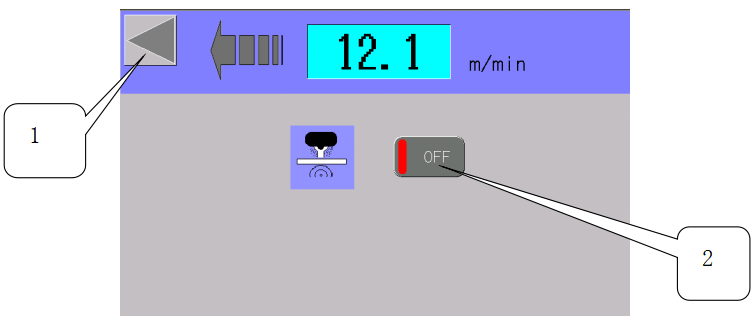

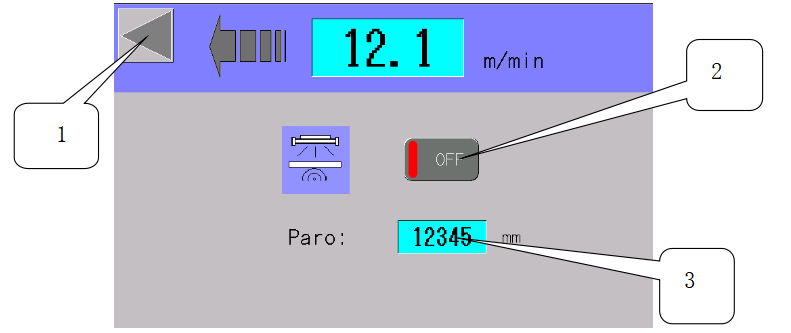

ikhombisa isivinini esisethiwe sokusebenza komshini, thinta izithonjana ezihlukene zibe imodi yamapharamitha, bese uhlela amapharamitha.

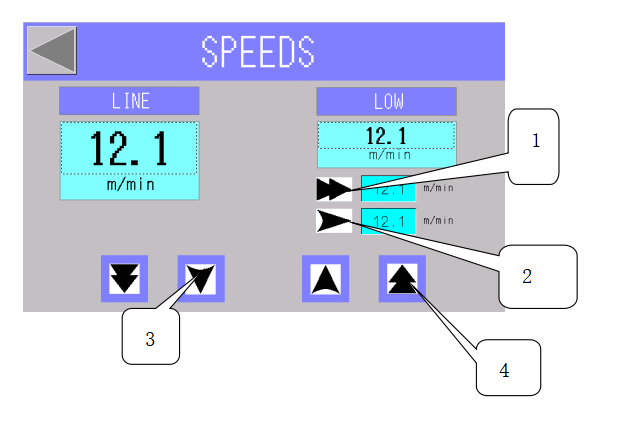

2.2.1 isivinini sesethi esibonakalayo

UMUGQA: isivinini somsebenzi womshini

LOW: isivinini esiphansi somshini

1, Lesi sithonjana esesamba sesivinini somugqa, ukukhuphuka kwesivinini somugqa noma ukunciphisa inani elithile uma ukuthinta everytime.it is can touch to set.

Lesi sithonjana esesamba sesivinini somugqa, ukukhuphuka kwesivinini somugqa noma ukunciphisa inani elithile uma ukuthinta everytime.it is can touch to set.

2, Lesi sithonjana singesenani lokunyuka noma ukunciphisa isivinini somugqa.singathinta ukuze sisethwe.

Lesi sithonjana singesenani lokunyuka noma ukunciphisa isivinini somugqa.singathinta ukuze sisethwe.

3, Lesi sithonjana singenani lejubane lomugqa elincishisiwe ngaso sonke isikhathi.

4, Le incon ingeyenani lokukhuphuka kwesivinini somugqa ngaso sonke isikhathi.

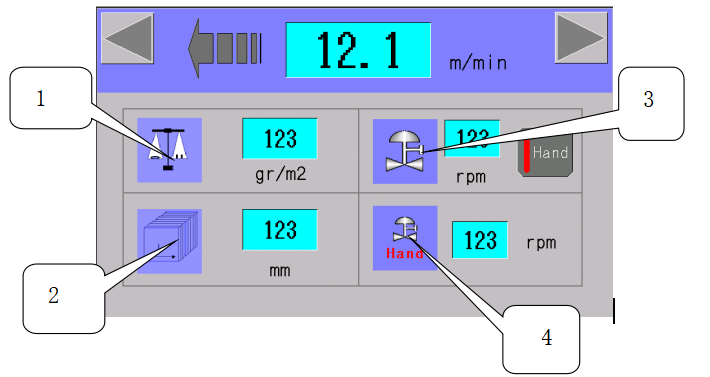

2.2.2 Uhlelo olusethiwe esibonakalayo

Lawula inani le-PUR ngokuzenzakalela ngokulungisa isivinini sepompo ye-PUR, faka nje inani le-PUR nobubanzi be-foil, isilawuli sizolungisa isivinini sepompo ukuze sisakaze inani elizenzakalelayo.Futhi ijubane lokusabalalisa elilawulwa ngokwejubane lokuphakelayo ngokuzenzakalelayo.

ukusebenza kungaba okuzenzakalelayo noma okwenziwa ngesandla:

imanuwali:Iphampu ye-PUR igijima njengejubane elimisiwe, akukho lutho lokuphakela isivinini nobubanzi be-foil

okuzenzakalelayo: Isilawuli silungisa isivinini sepompo ngokuzenzakalelayo ngokuya ngenani le-PUR elidingekayo.

1, inani le-PUR elimisiwe: faka inani le-PUR njenge-g/m².lisebenza kuphela kumodi ezenzakalelayo.

2, isethi yobubanzi be-foil: ububanzi be-foil, fanisa ne-PUR nozzle.

3, isivinini sepompo: bonisa isivinini sepompo ngomumo kuphela ongashintsha phakathi kwemodi yezandla ne-othomathikhi.

I-4, isivinini sepompo esenziwa ngesandla: Isivinini sepompo kwimodi yezandla, thinta ukuze usethe.

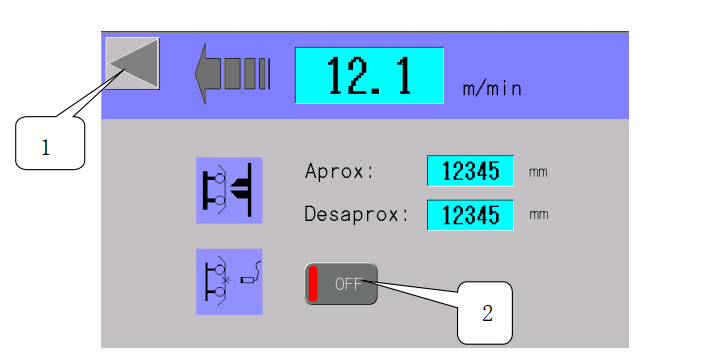

2.2.3 I-PUR spread set interface

Lo mshini uhlome umbhobho wokusabalalisa i-foil, ethole amaswishi e-photoelectric, eyodwa yokuphakela izinzwa, enye ye-sensor nozzle eduze ne-foil ngohlelo lwe-pneumatic.

Ukuphakelwa kwenzwa yokushintsha ugesi wesithombe nokusondela, isilawuli sizoqala iphampu ye-PUR ukuze sinikeze i-PUR.Isivinini sephampu sisethwe kusilawuli.

1, umlomo wombhobho has 2 umsebenzi izindlela ukukhetha panel control:

imanuwali: khetha kuphela emshinini wokulungisa iphutha noma wokulondoloza, i-valve yokulawula i-solenoid IVULIWE.

okuzenzakalelayo: Isilinda somoya siphusha umlomo ku-foil, qala iphampu ye-PUR bese usakaza i-PUR ku-foil kuya ekugoqweni, lapho uphakela inzwa.Kukhona inkinobho yokuvikela ku-nozzle, umlomo wombhobho uzoyeka ukusabalala futhi ubuyele endaweni elindile, lapho ifoil iphuka, iswishi yokuvikela ayikwazi ukuzwa i-foil kumodi yokusebenza ezenzakalelayo.

1, I-ESC iyeka i-PUR set interface;

2, VULIWE/ VALIWE: Lawula futhi uvale inkinobho yokuphepha.

I-Aprox:I-Nozzle push-in pulse counter, bala lapho uncelisa iphrofayili.Okokulungisa lapho isilinda somoya siphusha umlomo wombhobho ukuze sisebenze.

I-Desaprox:Nozzle backward pulse counter, bala lapho iphrofayela yokugcina iphuma nini.Okokulungisa lapho umlomo wombhobho ubuyela endaweni elindile.

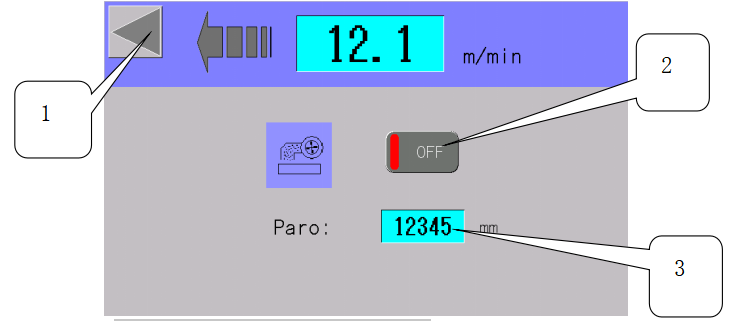

2.2.4 Isixhumi esibonakalayo esisethiwe se-airgun

Umsebenzi khetha ewindini le-pop.

sebenza ngokuzenzakalelayo kulezo zimo:

1, i-photoelectric efakwe emnyango wokuphakela.

2, inkinobho yokuthinta IVULIWE isimo.

3, isistimu yokushayela iyasebenza.

1.quit hot airgun set interface.

2.Vula noma uvale i-airgun eshisayo

3.I-Paro: Uma iswishi ye-photoelectric ingakwazi ukuncelisa inzwa lapho i-airgun eshisayo iqala, i-airgun izobala ukuze icishe, ipharamitha iyalungiseka.

2.2.5 i-brush set interface

Umsebenzi khetha efasiteleni likapapa

Ibhulashi qala futhi ume ngokuthinta inkinobho VULA/VALA.

Qalisa ibhulashi lapho umshini usebenza.

1.yeka isethi esibonakalayo

2.ON/OFF: Qala futhi umise umsebenzi wokuxubha

2.2.6 izibani zokufudumeza zisethwe esibonakalayo

umsebenzi okhetha ngamalambu okushisa esikrini sokuthinta uqala ngokuzenzakalelayo kulezo zimo:

1, i-photoelectric efakwe emnyango wokuphakela.

2, inkinobho yokuthinta IVULIWE isimo.

3, isistimu yokushayela iyasebenza.

1.yeka isethi esibonakalayo

2.ON/OFF: qala futhi umise izibani zokushisisa.

3.Paro:Amalambu okushisa ayaqala, kodwa iswishi ye-photoelectric ayikwazi ukuphakela izinzwa.Izibani ezishisayo zizobala phansi ukuze zime ngokuzenzakalelayo, le parameter iyalungiseka.

Ⅲ, ukugcinwa kwe-nozzle

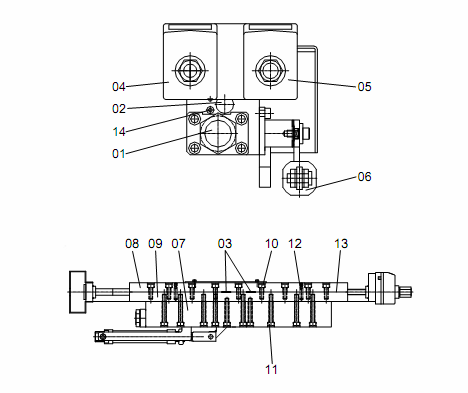

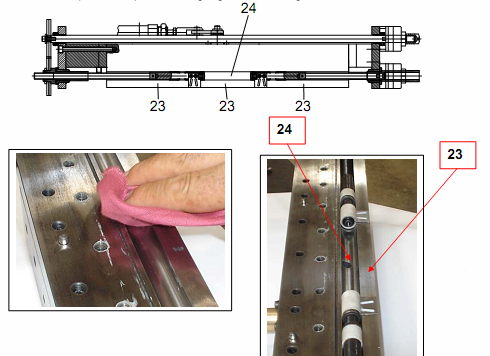

3.1 isakhiwo

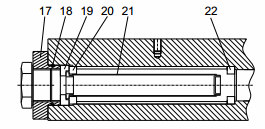

01:nozzle nesixhumi sepayipi 02:ukushisisa ukumelana

03:I-PUR yokulungiswa kwe-gasket yokusabalalisa 04:isikhundla se-counter kwesokunxele lungisa

05:isikhundla sekhawunta yesokudla lungisa 06: susa isilinda

07:umzimba wombhobho 08: ikhava yangaphezulu yenozzle

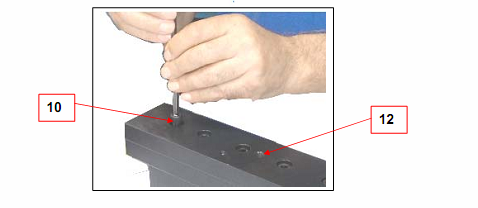

09: ikhava engaphansi ye-nozzle 10: isikulufu sokulungisa umlomo wombhobho

11:isikulufu sokulungisa umlomo wombhobho 12: iphinikhodi yokumisa

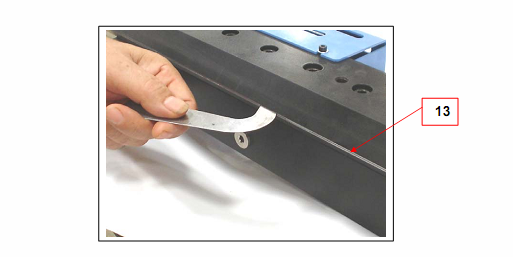

I-13: izikhala ze-gasket eziguquguqukayo 14: i-temperature probe

3.2 ipharamitha

iminithi ububanzi: 25mm

ububanzi obukhulu: 330mm

amandla okushisa: 1000W

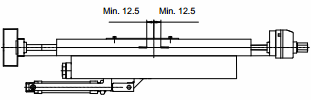

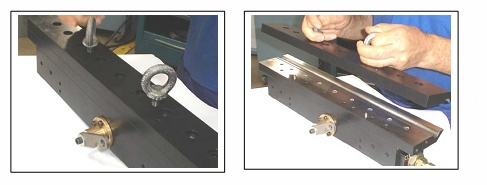

3.3 ukulungiswa kobubanzi bokusabalalisa

Khipha isibali sesokunxele nesokudla ukuze ulungise ububanzi bokusabalala, isamba sezinombolo kwesokunxele nesokudla sisakaza ububanzi.

Isexwayiso sokusebenza

Ububanzi bokusabalalisa bulungiswa kuphela lapho i-PUR kanye ne-nozzle kufinyelela izinga lokushisa lomsebenzi, ayikwazi ukulungisa ngaphandle kwezinga lokushisa lomsebenzi, noma i-gasket izolimala ku-screw puch.

Kufanele ilungise kancane, ayikwazi ukushesha, noma ukulimala kwe-gasket.

Ububanzi obuncane bokulungiswa kwe-gasket ngayinye bungu-12.5mm, uma bungaphezu kobubanzi, ukulungiswa kuzozenzakalelayo.

Ikhawunta yesikulufa izoba nzima Uma ububanzi bulungiswa bube buncane noma bube bukhulu.Kufanele imise isikulufu, noma izolimala.

3.4 Ukugcinwa konozi lwePUR

3.4.1 ukugcinwa kwansuku zonke

3.4.1.1 umqhubi kufanele enze ngaphambi komsebenzi

1, ukushisa umlomo wombhobho ukusebenza izinga lokushisa

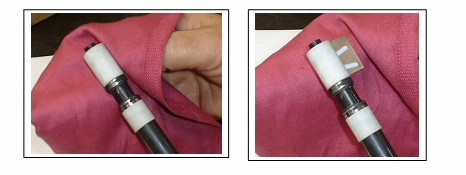

2, hambisa ishidi elincanyana ukuze uhlanze i-slot kalula (13);

3, ukulungiswa kobubanzi bokuhlola kusuka ku-min kuya ku-max (03) futhi bagcine okuvamile noma cha;

4, lungisa ububanzi (03) ukuze usebenze isimo

5, futha i-PUR kuze kuphume ipayipi nombhobho

6, ingxenye esabalele ehlanzekile nekhava yangaphezulu (08).

3.4.1.2 umqhubi kufanele enze njalo ngemva komsebenzi

1, gcina izinga lokushisa le-nozzle

2, hambisa ishidi elincanyana ukuze uhlanze i-slot kalula (13);

3, ukulungiswa kobubanzi bokuhlola kusuka ku-min kuya ku-max (03) futhi bagcine okuvamile noma cha;

4, vala ububanzi(03) ukuya kwamaminithi angu-12.5mm

5, umlomo wombhobho

3.4.2 isondlo samasonto onke

3.4.2.1 umqhubi kufanele enze kanjalo lapho umshini ucisha

hlanza noma shintsha isihlungi

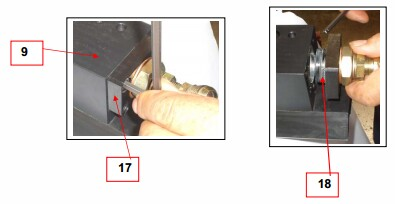

1, vula isihlungi se-nozzle (17);

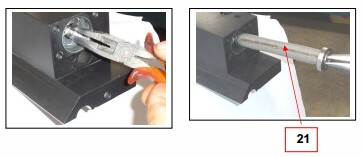

2, bhidliza isihlungi (21);

3, shintsha isihlungi esisha esihlanzekile kusixhumi (18).

Gcoba isihlungi esingcolile ku-solvent isonto elilodwa ngokubekwe eceleni

ukunaka: ungacwilisi i-sealer ku-solvent (18)

3.4.3 Ukuhlakazwa nokugcinwa komlomo wombhobho

I-Nozzle iyithuluzi eliguga kalula, ngakho-ke kufanele uqaphele lapho uyiqaqa, futhi uqaqe izinga lokushisa lomsebenzi.Noma limaza i-nuzzle ekuvuzeni noma iphutha le-PUR.

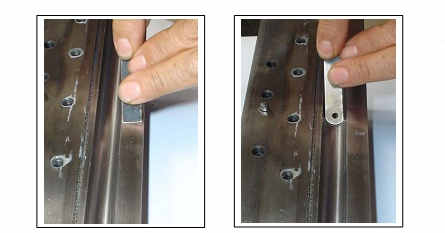

landela izinyathelo ezingezansi ukuze uhlukanise i-nuzzle:

1, thatha igilavu yokuphepha

2, isikulufa sokulungisa i-nuzzle (10);

3, khulula isikulufu sokulungisa sekhava yangaphezulu (08), qaqa iphini lokubeka (12) kusuka kukhava engezansi (09)

4, hambisa ikhava engaphezulu ngokucophelela bese uzobona ishidi lokulungiswa kwangaphakathi .ungaphahlazeka (03);

5, khipha iglue ye-PUR engakwesokunxele

I-6, ishidi lokulungisa elihlanzekile eline-solvent (03);

7, bhala i-glue off top and bottom cover with metal sheet ngokucophelela, ungalimazi.

8, idivaysi ye-nozzle ehlanzekile ene-solvent, ishidi lokulungisa ngokukhethekile (03).

9, Faka agodliwe indlela yokudiliza.

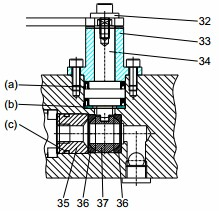

3.4 shintsha i-sealer

1, khetha ukwesekwa kwesihlungi (9);

2, khetha i-sealer (15);

3, khetha indandatho (a) kanye (b);

4, khetha i-glue switch (16);

5, susa isikulufu (17), susa ibha yokushayela (18);

6, susa i-nozzle sealer (c) kanye (d);

7, susa i-valve switch (19) kanye ne-sealer (e);

8, hlanza izingxenye zethu ezisusiwe bese ugoqa imbobo nge-solvent.

9, isidingo sokushintsha uphawu (c) noma nini lapho uhambisa ibha yedrayivu, noma kuzoba ukuvuza kweglue;

10, faka i-reverse dismantle way.

Ⅳ, uhlelo lwesifunda

Isikhathi sokuthumela: Jun-06-2022